Ejector Venturi Scrubber All Products

Principles of operation

Ejector-Venturi Scrubbers utilize the energy of the scrubbing liquid to effectively entrain and remove noxious gases, particulates odors, fumes, and dusts from the gas. The particulates are removed through impaction of the solids by the high velocity spray liquid. Gaseous pollutants and odors are removed through absorption and/or chemical reaction between the gases and scrubbing liquid. The ejector action, in addition to providing effective scrubbing, also produces an air moving and/or static pressure boosting capability for the system.

How the Ejector-Venturi Scrubber Works

Contaminated gas is drawn into the Ejector-Venturi Scrubber by means of the ejector action of a high velocity liquid spray directed into a venturi throat. This high velocity spray is generated by the motive liquid pressure. The spray impinges on the venturi throat to induce the draft-producing action. The venturi throat is a high turbulence zone where maximum gas-liquid contact and mixing occur. It is this intimate contact which produces effective scrubbing. The scrubbed gases then leave the throat area with the contaminants impacted or absorbed into the scrubbing liquid. The diverging section is designed to regain as much as possible of the system energy and to reagglomerate the scrubbing liquid droplets for ease of entrained separation. The cleaned gases with entrained contaminated droplets discharge from the scrubber to a gas-liquid separator.

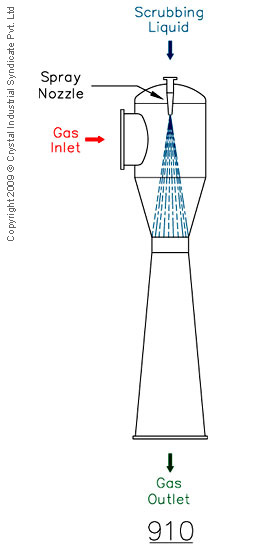

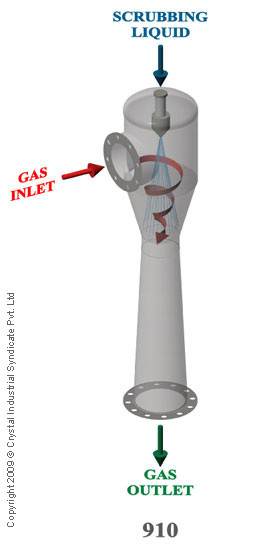

TYPE 910

The Type 910 Standard Ejector-Venturi Scrubber has a radial side gas inlet, bottom gas discharge, and top motive liquid inlet.

TYPE 911

The Type 911 inline Ejector-Venturi Scrubber has a top gas inlet, bottom gas discharge, and side motive liquid inlet. The Type 911 scrubber is used where an inline configuration simplifies the process equipment layout.

TYPE 912

The Type 912 Wet Approach Ejector-Venturi Scrubber has a universal gas inlet, bottom gas discharge, a top motive liquid inlet, and a side wall flush liquid inlet. The wet approach feature provides a fully flushed wet/dry line interface where hygroscopic materials are prevented from building up and plugging the unit.

In technical collaboration with Severn Trent Services